Category: News

At Masterpress, we are proud to announce a pivotal expansion that marks a nearly 40% increase in our production capacity. This milestone is a reflection of our commitment to meet the growing demand for high-quality, decorative, and functional printed packaging solutions that stand out from the crowd across key European regions.

With significant investments at our Białystok facility, we have introduced two new sleeve printing machines, enhancing our output by approximately 16 million square meters annually. This expansion not only addresses the current customer demand in France, the DACH region, and BENELUX but also lays the groundwork for future growth.

“At Masterpress, we strive to be a manufacturer that can be relied upon, that is constantly improving and that actively responds to the individual needs of each customer,” said Jeroen de Haan, general manager of Masterpress. “For the last 27 years, and since the early beginnings of the company, we have endeavored to partner closely with our customers, seeking to provide tailored, creative and functional printed decorative packaging solutions that help their products stand out from the crowd.”

The new 12-station and 14-station hybrid printing machines not only enhance our creative capabilities but also boast energy-efficient UV LED drying and the capacity to print on films as thin as 12 microns, driving us towards more sustainable packaging solutions.

We are also delighted to welcome Erwann Paugam to the Masterpress team as the new Sales Director. Bringing a wealth of expertise in the shrink sleeve industry, Erwann is set to be a cornerstone in our strategy to fortify our presence in Europe.

As we project our growth into the future, our ambition is clear: to double our revenue in the next 5 to 10 years and to strengthen our physical presence within European markets. This aligns with our vision to deliver unmatched value to our customers through creative, reliable, and functional decorative printed packaging solutions.

Our inventive and “designed-for-recycling” packaging products have been widely recognized by industry across Europe. The most recent accolades include two AWA Alexander Watson Associates Sleeve Label Awards. Masterpress’ TINE 300g Dairy Cup Sleeve produced for TINE SA won in the Environmental Winner category, and Żubrówka Black Limited-Edition packaging created for CEDC International was recognized as the Best of Show packaging.

Together, we are setting new standards for excellence and sustainability in the packaging industry.

Project entitled Implementation of the R&D Findings Leading to the Production of unique shrink sleeve labels with innovative perforation and effective convex and tactile printing under Measure 3.2 Support for R&D results implementation,and Sub-measure 3.2.1 Research for the market of the Intelligent Development Operational Programme, 2014-2020

We are very proud to announce our recent achievements with two prestigious AWA Sleeve Label Awards, recognizing excellence in label printing for two products: the TINE 300g Dairy Cup Sleeve for TINE and the Żubrówka Black Limited-Edition packaging for CEDC.

TINE 300g Dairy Cup Sleeve

The judging criteria for the AWA Sleeve Label Award focused on various aspects of the printing process, including registration, color complexity, and graphic alignment. Our combination of printing methods allowed us to achieve superior results and exceptional print quality.

Our TINE 300g Dairy Cup Sleeve sets a new standard for sustainable packaging. This label is more than just visually appealing; it aligns with the concept of “designed-for-recycling” packaging set by RecyClass. The innovation lies in our choice of materials. By using a low-density polyolefin shrink sleeve material, we’ve created a “mono-material-like” solution that facilitates proper identification and recycling of the cups in the correct polymer stream.

Our journey to sustainability didn’t stop there. We initially developed the sleeve with polyolefin 50µ but transitioned to 45µ, effectively reducing the material used. By reducing the amount of material in the sleeve, we’ve lowered the carbon footprint and taken a significant step towards eco-friendlier packaging solutions. We’re proving that shrink sleeves can be a “good-for-recycling” solution, addressing the growing concerns about single-use plastic waste. Label for the limited edition of Żubrówka Czarna.

Our second award-winning proposal is a limited edition shrink sleeve label for Zubrowka Black

Hybrid printing technology allowed us to achieve exceptionally detailed and clear gold elements on a deep, elegant black background creating a stunning visual effect that makes the limited edition Zubrowka Black stand out on the shelf.

Our shrink label, that design was inspired by the crystal-clear water from the springs of the Bialowieza Forest and the oak charcoal filtration process, depicts metallic winter plants and snowflakes with extraordinary precision.

As an added bonus, our sleeve features perfectly spaced and almost invisible perforations, making it easy to remove the label before recycling the glass bottle.

Why These Entries Deserve to Win:

Every brand seeks to distinguish itself through packaging, with the goal of connecting with consumers through their visual senses and quality. The TINE 300g Dairy Cup Sleeve and Żubrówka Black Limited Edition beautifully achieve this goal.

“We are honored to have our work recognized, and it inspires us to continue pushing the boundaries of label design and application” – said Waldemar Zdrodowski, CEO of Masterpress.

The AWA International Sleeve Label Awards 2023 – Alexander Watson Associates

We’re thrilled to announce that Masterpress has been recognized with the award of “Best Employer 2023” by the Polish Chapter of the Social Responsibility Leaders Program. This recognition reflects our commitment to developing and building good relationships with employees and creating a workplace that values the knowledgeable contributions and printed packaging expertise of ours.

“We are very proud to receive this award, confirming that our efforts to create a friendly, open, and diverse workplace conducive to employee development are being noticed and appreciated. From the beginning of the company, our employees have been our greatest asset. I hope each of them knows that they can grow with us, talk openly with us and fulfill their professional ambitions” – said Waldemar Zdrodowski, CEO of Masterpress in an article for Business Forum.

At Masterpress, our employees are at the heart of everything we do. We believe in investing in their growth, providing professional support, and creating an environment that encourages creativity and inventiveness. Our success is a result of their dedication, and this recognition reaffirms our commitment to their well-being and professional development.

Read more (PL):

We are thrilled to announce that Masterpress SA is a proud sponsor of the upcoming AWA International Sleeve Label Conference & Exhibition 2023. Our commitment to supporting cutting-edge technology initiatives and environmentally sustainable solutions within the shrink sleeve industry has driven us to join hands with this prestigious event.

The AWA International Sleeve Label Conference & Exhibition has always been a significant milestone in the sleeve label industry calendar, and this 17th edition is poised to be truly exceptional. The theme, “Connecting the Shrink Sleeve Labeling Industry,” resonates deeply with our mission to foster innovation, growth, and sustainability through collaboration and knowledge sharing.

Here’s a sneak peek at what you can expect from this event:

Market & Industry Insights: Explore the latest trends, market developments, and best practices that are shaping the sleeve label industry. Prepare to be inspired by informative presentations and a thought-provoking keynote speech.

Technology & Developments: Dive into the cutting-edge solutions, innovations, and industry developments that are revolutionizing the sleeve labeling landscape. Engage in discussions with experts who will share their insights, challenges, and success stories.

Sustainability & The Future: At AWA, sustainability is at the forefront of our agenda. Join us in exploring eco-friendly materials, recycling initiatives, and circular economy solutions, and discover the latest strategies for minimizing environmental impact.

Connecting with Brand Owners: Gain invaluable insights from brand owners themselves as they share their perspectives, challenges, and expectations. This unique opportunity to hear directly from brand owners will provide a fresh perspective for all participants.

AWA Sleeve Awards: Celebrate excellence as we honor exceptional achievements, groundbreaking innovations, and remarkable contributions within the sleeve label sector. Be inspired by the remarkable work shaping our industry.

Don’t miss this unparalleled opportunity to stay ahead of the curve and establish lasting connections with industry leaders. Secure your spot today and be part of the future of sleeve labeling!

Join us in connecting professionals from across the sleeve label value chain. Sign up today and be a part of this exciting journey!

We are glad to announce that Masterpress received the RecyClasss Letter of Compatibility “design for recycling” when using our shrink sleeve solution on dairy cups. Our sleeve label applied onto a PP cup, has been awarded a positive recyclability assessment from the RecyClass association.

We submitted our packaging solution for assessment by Suez.circpack®. The tests were conducted according to RecyClass methodology.

Following the performed tests, Masterpress was granted a “Letter of Conformity”, confirming that the assessed product met the requirements of compatibility with readily available sorting and recycling technologies commonly used at industrial scale in the recycling sector in Europe. It means that during the recycling process the cup will be directed straight to the rigid polypropylene fraction recovery stream, without the need of prior removal of the sleeve.

The solution developed by Masterpress is environmentally friendly and fits well with the principles of circular economy.

We are proud to announce that as of June, 2021, Masterpress has had its own apiary of 6 hives. The bee houses have been located on an undeveloped, grassy piece of the company’s grounds, several dozen meters from Masterpress’ production facility. The location of the hives ensures the safety of employees on the one hand and on the other hand will guarantee that insects will not be disturbed. Additionally, a board with information on the apiary, bees and safety rules will be placed in the vicinity. The hives have been provided by local beekeeper, who will also take care of the bee families.

Urban beekeeping has been undergoing a dynamic development in recent years. And that is very good, as bees are a crucial element of our whole ecosystem. The accumulated experience and scientific research have proven that urban environment excellently suits honey bees. Through an intensive pollination of flowers the bees contribute to improving the urban flora, trees in particular. Insects that live in urban areas are not threatened by the harmful effects of pesticides and other chemical sprays, which is often the case in rural areas. They also benefit from the air temperature, which is usually slightly higher in cities. The city bees do not have to fiercely compete with other insects for access to flower nectar, which translates into relatively high honey production and other apiculture products.

Masterpress’ local beekeeping initiative is an expression of our employees’ concern for the natural environment and, at the same time, an effect of the company’s wide perspective on the sustainable development strategy, which perfectly fits into the company’s value system. This way we also show that even such localized, small-scale positive initiatives can have a greater effect on the society at large.

We are very pleased to announce that Masterpress has received the FSC® Chain of Custody certificate. The certificate applies to the purchase of unprinted self-adhesive paper labels which have been certified in the „FSC Mix” or „FSC Recycled” category and the sale of already printed certified labels.

Masterpress has been consistently carrying out a sustainable development strategy for many years based on the principles of corporate social and environmental responsibility. We are implementing such principles in our day-to-day work, e.g., by rationally managing the use of natural resources, applying modern technological solutions which facilitate more efficient consumption of water and energy, or reducing harmful emissions to the environment. Masterpress’ decision to undergo the demanding FSC® certification procedure is another step within our sustainable development strategy.

Our FSC® certificate translates to practical benefits for Masterpress, our business partners, as well as the natural environment. Above all, it ensures that FSC®-certified self-adhesive labels are made of raw materials legally sourced and processed in a supply chain that complies with FSC standards. This means that the paper in our labels has been made either from wood that comes from responsibly managed forests or from recycled material. This is our way of taking care of woodland ecosystems and protecting the vitality and biological resources of forested areas. In doing so, we contribute to preventing adverse climate change on our planet.

About FSC®

FSC® (Forest Stewardship Council®) is an international non-profit organization that promotes responsible management for the world’s forests. It has also established a system for the certification of forests and wood and paper products. The FSC® system is one of the most reliable global forest certification systems, officially recognized by world’s leading environmental organizations.

Masterpress is a printed packaging solution provider to many international and regional brands, and we are committed to helping our customers solve their sustainability in packaging challenges.

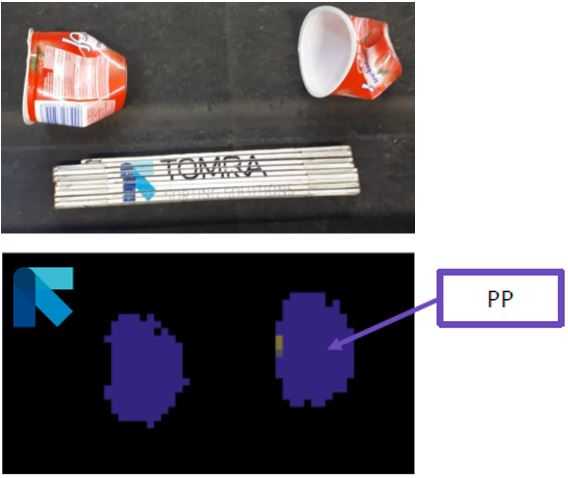

In 2019, Masterpress developed a decorated PP cup solution designed for recycling and validated the development externally last year with TOMRA Germany. The test was conducted to verify that cups with Masterpress shrink sleeves would be identified as a mono-material rigid PP solution, a critical step to properly sort the plastic containers into the appropriate recycling stream. The test was performed on the TOMRA AUTOSORT machine with a belt operating speed 3 m / s. According to the TOMRA report, Masterpress shrink sleeves on a PP cup is detected as mono-material rigid PP.

Pic. TOMRA tests result (source TR_20200127_TOMRA_Masterpress)

Contact us to request the full report or to learn about our complete range of sustainable packaging solutions!

About Moskovskaya Osobaya shrink sleeve

A Chinese dragon is a legendary creature in Chinese mythology, Chinese folklore, and the Chinese culture at large. Chinese dragons have many animal-like forms such as turtles and fish, but most are commonly depicted as snake-like with four legs. They traditionally symbolize potent and auspicious powers, particularly with control over water, rainfall, typhoons, and floods.

The cultural importance and intrigue for dragons was design inspiration for the sleeve label of the Moskovskaya Osobaya bottle dedicated for the Asian market. In the daylight, the bottle presents a powerful dragon highlighted with metallic gold details, but the magic begins when the label is exposed to UV light. Various shades of bright fluorescent green and pink awakens the bottle dragon with a spectacular luminous effect, grabbing attention throughout the night.

Moskovskaya Osobaya is a premium vodka brand produced by Amber Beverage Group.

Moskovskoya Osoboya UV sleeve presentation video

Masterpress was presented the AWA International Sleeve Label Awards 2020 certificate for the label of the limited edition Stock Prestige Grand Prix.

About Stock Grand Prix shrink sleeve

The inspiration for the black bottle was the Grand Prix races, events often associated with luxury and exclusiveness. Checkered Flags and sport tires are elements representative of racing events, and these were focal elements to integrate in the graphic design of the sleeve label. Masterpress’ hybrid print technology was employed to produce the rubber-like effect of tires onto the shrink sleeve labels. Through experience and modified print techniques, our expert R&D team succeeded in obtaining the deep black color and improved scratch resistance for the soft-touch matte texture of the label’s surface, which imitate the look and feel of smooth rubber.

AWA Sleeve Label Awards 2020 presentation video

AWA Sleeve Label Awards 2020 from AWA Alexander Watson Associates on Vimeo.