Category: News

Join us at booth E2.23 during the Warsaw Pack trade fair, taking place from April 8th to April 10th, 2025, in Nadarzyn near Warsaw. This is your chance to explore our advanced shrink sleeve application machines and discover our extensive range of shrink sleeve and pressure-sensitive labels.

Warsaw Pack is more than just a trade fair—it’s an opportunity to connect, exchange ideas, and stay ahead of industry trends. Visit our booth to discuss the latest developments in labeling and packaging technology and see how our expertise can benefit your business.

Don’t miss the chance to meet us and explore the future of packaging. See you at Warsaw Pack!

Please note that Masterpress will be closed from December 24th to December 29th, 2024, as well as on January 1st and January 6th, 2025.

All messages received during this time will be addressed once we return to work.

We wish you a joyful holiday season and a Happy New Year!

We recently took part in the AWA (Alexander Watson Associates) International Sleeve Label Conference & Exhibition 2024 in Miami, where our team had the chance to contribute to important industry discussions.

Our General Manager, Jeroen de Haan, joined a panel on “The Future of Sustainability and Packaging,” where he shared our experiences alongside other industry professionals, exploring the challenges and in sustainable label opportunities in packaging.

R. Gabriel Magdaleno, our Strategic Product Management & Marketing Director, presented “Mastering Sleeve Label Excellence: Sustainable Innovations.” He discussed our award-winning custom label solution for TINE SA, focusing on how innovation and sustainability came together in our shrink sleeve solutions within the labelling industry.

As in previous years, Masterpress’s participation at this event underscores our ongoing commitment to developing products and designed for recycling solutions that align with evolving industry trends. Engaging in these discussions allows us to continuously refine our approach and contribute to the future of packaging.

Join Masterpress at FACHPACK 2024 from September 24 to 26 in Nuremberg, where we’ll showcase our latest sustainable packaging solutions for the FMCG industry. Explore our Pressure Sensitive Labels and shrink sleeve labels, designed for premium branding, and discuss our label application machines as well as sustainable solutions for the e-commerce sector.

We’re also excited to present our two award-winning sleeve labels that have earned international recognition for sustainable contribution and best in class. Our innovative monolayer pouch—a cutting-edge, eco-friendly packaging option that delivers outstanding performance while supporting your sustainability goals will also be unveiled at this year’s event.

Find us in Hall 5, Stand 5-161 to discover how our packaging can help your brand stand out and succeed in the competitive FMCG market.

Don’t miss out—let’s shape the future of packaging together!

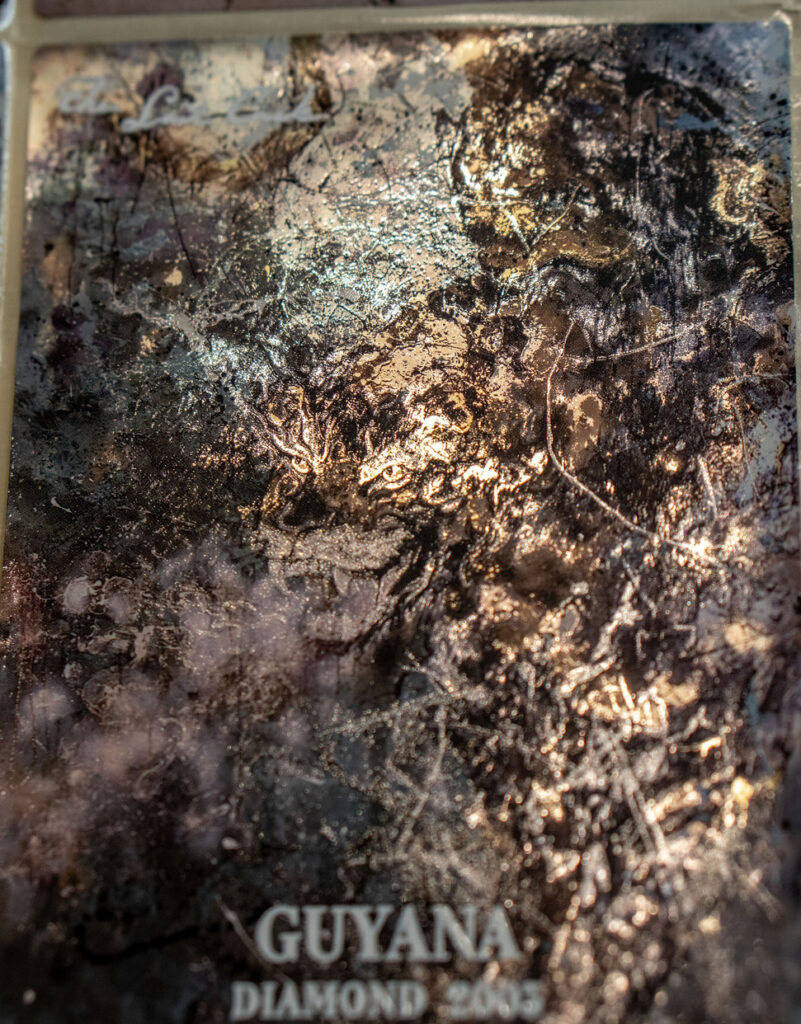

A hybrid approach to label printing encourages innovation and flexibility in the client-customer relationship, delivering unique, elegant and durable labels for Distilia’s high-end, collectible bottles.

Masterpress has recently completed a niche labelling project for Distilia, an independent bottler of high-quality spirits specialising in selling unique bottles of rare, collectible alcohols. The project involved the production of five series of 250 exclusive labels using hybrid printing – Masterpress’s technique that combined digital printing, screen printing, lamination and varnishing – to achieve a distinctive, touch-sensitive, durable and visually striking effect.

Distilia, known for sourcing unique barrels and bottling exclusive batches, required labels that would not only mirror the luxury and exclusivity of their products but also captivate investors and enthusiasts at auctions. Unlike standard retail labels, these had to demonstrate superior quality and durability – essential characteristics for supreme and collectible items.

The company approached Masterpress with a pre-designed label featuring Yu Chaun’s real-life painting, aiming to integrate metallic elements and extenuate the painting’s intricate details. Considering the unique nature of the request, the challenge for Masterpress was to find the right technology to turn this vision into a captivating and exclusive label. “Our goal was to create something truly special – a label that reflects the heritage and sophistication of Distilia’s products while pushing the boundaries of conventional label printing and design,” said Artur Lesiński, business development manager at Masterpress.

“We wanted labels inspired by painted artwork that would capture the essence of our collectible spirits, showcasing their exclusivity and enduring quality,” said Jakub Bagiński, managing director of Distilia. “We had a clear vision and a ready design, but needed a partner that could turn this into reality. Masterpress achieved this with a blend of artistry and advanced printing techniques, which managed to capture even the paint brushes of the original painting and enhance the allure and premium nature of our products.”

“The project was something new for us, considering the label’s niche purpose and the fact we had to reproduce real art with all its details. At the same time, Distilia’s flexibility on how we should implement the label offered us an opportunity to see where we stand when it comes to our creative and technological capabilities,” said Aleksander Gajecki, digital printing manager at Masterpress.

Masterpress combined multiple technologies – digital printing, screen printing, lamination and varnishing. This combination of digital printing with different finishing techniques enabled the company to achieve a distinctive, touch-sensitive, and visually striking label. The label was printed on silver paper with a soft touch and laminate finish, creating a combination of paper and foil to make the connection soft and noble.

Thanks to digital printing’s flexibility and capabilities, Masterpress was able to test various solutions and complete the adjustments quicker, while reducing costs – efficiently consulting new versions with Distilia. Additionally, the use of digital printing contributed to reduced water, energy and paint consumption, coupled with less waste throughout the manufacturing process.

“Masterpress’s printing capabilities [digital printing] allowed for unprecedented levels of detail and colour fidelity. Each label meticulously incorporates special lacquers and metallic finishes, achieving a noble shade of gold, creating a really unique, tactile experience,” Distilia’s managing director Jakub Baginski highlighted.

“Trickling down” innovation for unique solutions and results

“Perhaps the best way to describe our experience working with Distilia on this project is ‘trickle down innovation’ – the technological freedom from the client gave us space for innovative hybrid solutions, and at the same time, room to provide flexibility across the whole manufacturer-client relationship,” said Artur Lesiński at Masterpress. “For example, we were able to deliver a high level of overprint, giving Distilia’s graphic designers more room to test new designs – and, thus, ‘trickling down’ innovation across our cooperation chain.”

Masterpress has comprehensively met Distilia’s expectations – from unique endurance and elegance to intricate aspects linked to the product’s advertisement, the company’s Managing Director reaffirmed. “Masterpress’s hybrid approach ensured that our designers had no limitations in the label design process,” Mr. Baginski added. “We wanted to reproduce the original images as best as possible. At the same time, the final visual effects were also key for us. We needed a label that looks as good – and even better – on pictures as it does on the shelf. Masterpress provided us with that exact product concept.”

“We always strive to meet our client’s expectations, in which the high-quality of the label plays a crucial role,” Mr. Baginski emphasised. “We were thus looking for a partner that could deliver a label that showcases the marriage of art, exclusive collection and consumption. Distilia is pleased to have found that in Masterpress with their innovative hybrid approach.”

Following the success of this project, Masterpress and Distilia have extended their collaboration, and are now working on a new label product.

About Distilia

Founded in 2018 by Jakub Bagiński and Piotr Kossowski, who together bring over ten years of experience in the premium spirits industry, Distilia has quickly made a significant impact. The company has become a notable brand among independent bottlers, providing official, bespoke, and white-label editions of whisky, rum, cognac, and armagnac. The company’s high-quality spirits have received numerous awards and developed a loyal customer base. By combining art and fine spirits, Distilia has launched impressive series such as The Sins Series, The Last Cask Series, and Karuizawa Five Decades. These products captivate both connoisseurs and collectors with their artistic presentation, including finely crafted wooden boxes, decorated bottles, elegant labels, and wax details. Distilia stands for uncompromising quality and unique products. For more details, visit www.distilia.com.

Siegwerk, one of the leading global providers of printing inks and coatings for packaging applications and labels, has announced the launch of its first full UV flexo deinking system for the European market: CIRKIT CLEARPRIME UV E02.

The new primer technology for non-food packaging applications offers a validated solution for safe and economic deinking of UV-printed self-adhesive labels (PSL). As a result, it improves the recyclability of labeled plastic packaging and enables the recovery of high-quality recyclates that are suitable for reuse in non-food packaging applications.

Although UV inks offer some advantageous properties for printing labels, they also pose a challenge for the subsequent recycling. “Depending on the substrate, UV inks are often very difficult to remove and can therefore lead to contaminations of recyclates, which significantly limits their further reuse,” explains Marc Larvor, Head of Technology Narrow EMEA at Siegwerk. “As a result, it is not surprising that UV-printed packaging has so far been considered as problematic in terms of a Circular Economy.” With CIRKIT CLEARPRIME UV E02, Siegwerk now offers a primer solution that specifically addresses this challenge. By enabling easy and safe deinking of UV-printed self-adhesive labels, it eliminates the need for prior label removal if the used plastics are compatible. “Such combined mechanical recycling of labels and plastic packaging can not only help to increase recycling rates, but also to save time and costs,” adds Marc Larvor. “Thereby, our new UV flexo deinking primer actively contributes to realize high-quality recyclates for circular waste streams.”

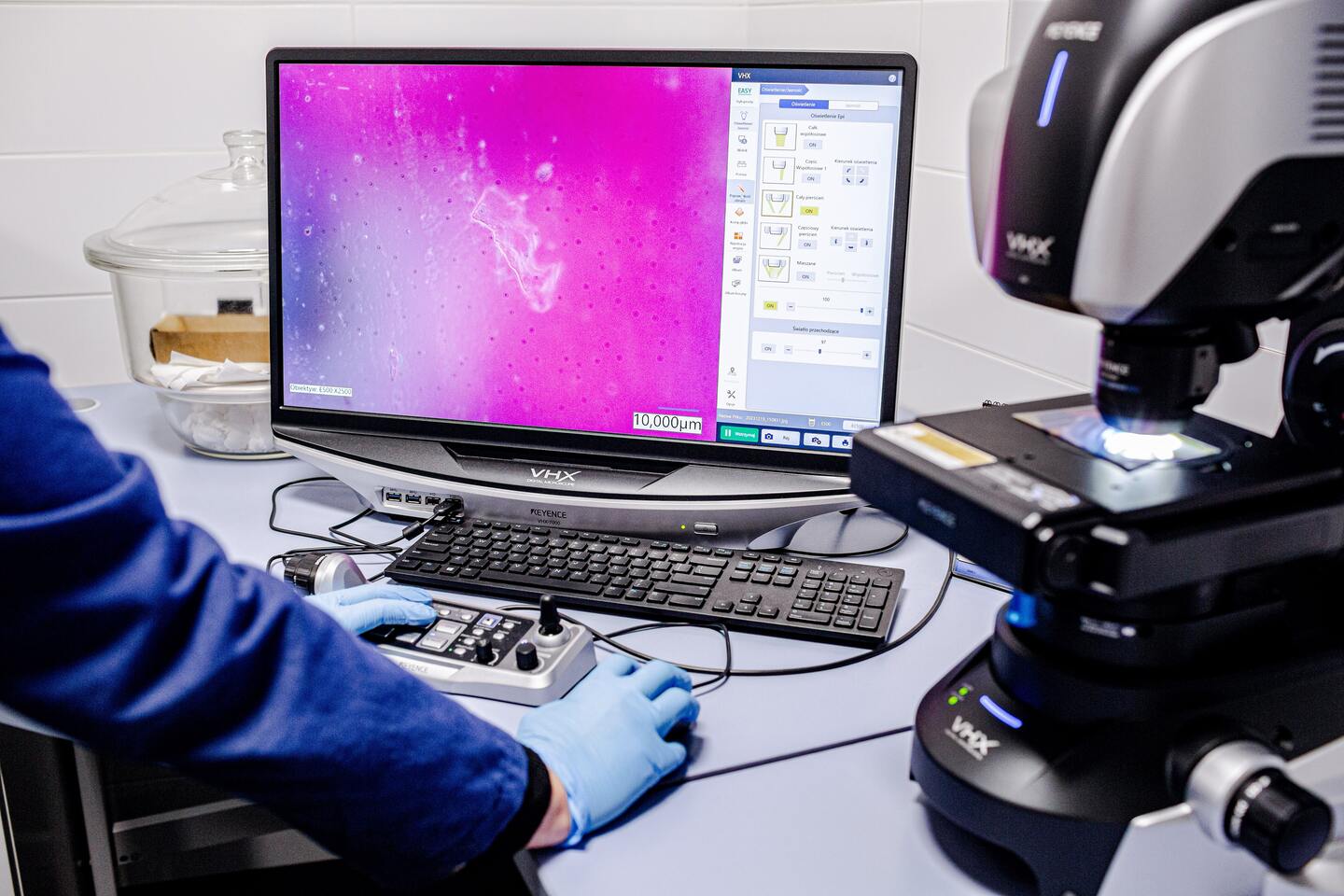

In a first field test with Masterpress Siegwerk’s new deinking primer has proven its effectiveness in all aspects. Masterpress’ research and development (R&D) experts used uncoated transparent or white pressure sensitive labels (PSL) made of PE85 and applied Siegwerk’s CIRKIT CLEARPRIME UV E02 followed by bleeding resistant UV flexo inks and an UV flexo OPV. First, the primer created a perfect adhesion between substrate and inks and later enabled full ink and varnish removal of the printed polyethylene (PE) film at standard deinking conditions based on the QT 507 washing protocol of the European PET Bottle Platform (EPBP). The primer layer also dissolved residue-free in the hot washing process and thus proved its ability to generate high-quality transparent or white recyclates, while the used non-bleeding ink formulations ensured a clean and reusable washing solution.

In-house laboratory tests at Masterpress and Siegwerk have shown great recyclate results underlining the effectiveness of the new deinking primer. “Consistently investing in its R&D laboratory, Masterpress brings state-of-the-art capabilities to test and trial new inks or materials before they enter the market. We are dedicated to advancing innovation within the shrink sleeve and self-adhesive label industry and are well positioned to help accelerate the commercialization of new, sustainable, recyclable products and materials on the market,” said Katarzyna Wasilewska, research and development manager at Masterpress. “Our tests confirmed an impressive recyclability of the UV-printed PE labels. Compared to other labels with no deinking technology, we could observe that contaminations of plastic recyclates due to discoloration could be massively reduced by using Siegwerk’s UV Deinking Primer.”

Therewith, CIRKIT CLEARPRIME UV E02 makes a significant contribution to improving the quality of recyclates and increasing their reusability. It works perfectly with the company’s established Sicura flexo series such as the non-low migration Sicura Flex 39-8 or the dual-curing series Sicura Flex Dual Cure. In addition, the new primer is compliant with different film materials and allows an inline printing of deinkable materials in a 100% UV-Flexo press setup keeping the complexity for users as low as possible. “With only three minutes, the new UV flexo primer even offers a deinking speed as fast as a water-based deinking primer making it to a great alternative for converters who are using a pure UV flexo press and are not able to process a water-based primer,” adds Katarzyna Wasilewska.

With CIRKIT CLEARPRIME UV E02, Siegwerk has not only added another functional coating solution to its CIRKIT product portfolio for packaging designs in the sense of a Circular Economy, but is also continuing to drive deinking as a new industry standard to further improve the recyclability of plastic packaging. Currently, the company’s portfolio of circular coatings already covers several water-based and solvent-based technologies for different applications, substrates, coating processes and performances: From barrier coatings against liquids, oil and grease, water vapor, oxygen, and UV light through heat seal and protection coatings to delamination and deinking primers.

To learn more about Siegwerk’s coating offering, please visit https://www.siegwerk.com/en/inks-coatings/coatings.html

Recent EcoVadis improvement to Silver aligns with company’s commitment to 42% Scope 1 & 2 GHG reduction target by 2030 as approved by SBTi

We signed the commitment letter to join the Science Based Targets initiative (SBTi). With a resolute focus on ethical and sustainable growth, the company aims to significantly curtail greenhouse gas (GHG) emissions, aligning with efforts to limit global temperature rise to 1.5°C above pre-industrial levels.

“By committing to set a roadmap for science-based emissions reduction targets within the SBTi, Masterpress is joining thousands of companies worldwide that believe we are all responsible and able to make a positive contribution to the health of our planet”, said Jeroen de Haan, general manager of Masterpress. “We aim to reduce our Scope 1 and 2 GHG emissions by 42% by 2030 from a base year of 2022 by improving the footprint of our own operations and by reducing the environmental footprint of our decorative packaging products for our end customers.”

Over the next couple of years, Masterpress will be working closely with the SBTi to validate its GHG emissions reduction roadmap for Scope 1 and 2 emissions aligned with the Paris Agreement which sets the goal of limiting global warming to 1.5°C. In addition, Masterpress will also work with SBTi to develop its Scope 3 GHG emissions target during this period.

“Importantly, this is not the beginning of a journey for Masterpress, where we have for many years been innovating with new, sustainable, recyclable products and materials on the market”, continued Jeroen de Haan. “But you cannot improve what you don’t measure. We have done and are doing a lot in this area, for example applying technologies to reduce packaging weight and film thickness, reducing the use of virgin plastic, and continually investing in energy-efficient equipment. We are committed to maintaining transparency in our actions and over the coming months, Masterpress will submit a concrete roadmap to SBTi for validation, further solidifying our commitment to sustainability.”

Masterpress acknowledges that packaging’s future lies in adopting the optimal materials and technologies, each contributing to environmental impact reduction therefore places great emphasis on the expanding of the research and development (R&D) lab to test and trial new sustainable products and solutions. For example, some of the actions Masterpress is taking to address this challenge:

- reducing of packaging weight and the optimization of packaging for specific products, such as the use of thinner films

- reducing the use of virgin plastic like testing plastic sleeve labels with 50% recycled content

- using of hybrid printing machines boasted with energy-efficient LED dryin

In a testament to its commitment to sustainability, Masterpress recently received EcoVadis Silver Certification demonstrating an improvement in the company’s sustainability management system rising from Bronze to Silver. This recognition places Masterpress among the top 15% of companies worldwide that meet strict sustainability criteria across four categories: Environment, Labor & Human Rights, Ethics, and Sustainable Procurement.

About SBTi: Science Based Targets initiative (SBTi) is an independent global body enabling businesses to set and validate emissions reduction targets in line with the latest climate science and strict criteria. The initiative is a collaboration between CDP, the United Nations Global Compact, World Resources Institute (WRI) and the World Wide Fund for Nature (WWF) and one of the We Mean Business Coalition commitments. Targets are considered “science-based” if they are in line with what the latest climate science deems necessary to meet the goals of the Paris Agreement – limiting global warming to well-below 2°C above pre-industrial levels and pursuing efforts to limit warming to 1.5°C. For more information, please visit www.sciencebasedtargets.org.

We are thrilled to announce our participation at the upcoming Warsaw Pack trade fair, scheduled to take place from April 23rd to April 25th, 2024, in Nadarzyn near Warsaw.Join us at booth E2.02B to experience firsthand our cutting-edge machinery designed for applying shrink sleeve labels. We will be also showcasing our shrink sleeve labels, PSL labels, and solutions for tea products like sachets and biodegradable tea tags.

Warsaw Pack is not just about showcasing products—it is about fostering connections and driving collaboration. We invite you to join us for insightful discussions, live demonstrations, and exclusive networking opportunities. Whether you’re a seasoned industry professional or just starting your journey in packaging, there’s something for everyone at our booth.

Don’t miss this chance to explore the future of packaging with Masterpress SA. Mark your calendars and make sure to visit us at Warsaw Pack. We look forward to seeing you there!

We are pleased to announce that Masterpress has been awarded the esteemed EcoVadis Silver certification. This recognition places us among the elite 15% of companies worldwide that meet stringent sustainability criteria.

This accomplishment underscores our dedication to continuous improvement and advancement. Transitioning from bronze to silver reflects our ongoing pursuit of enhancing our environmental performance and upholding responsible business practices.

As we move forward, we remain focused on driving positive change and setting new standards for sustainability within our industry. Thank you for your continued support as we pursue a more sustainable future.

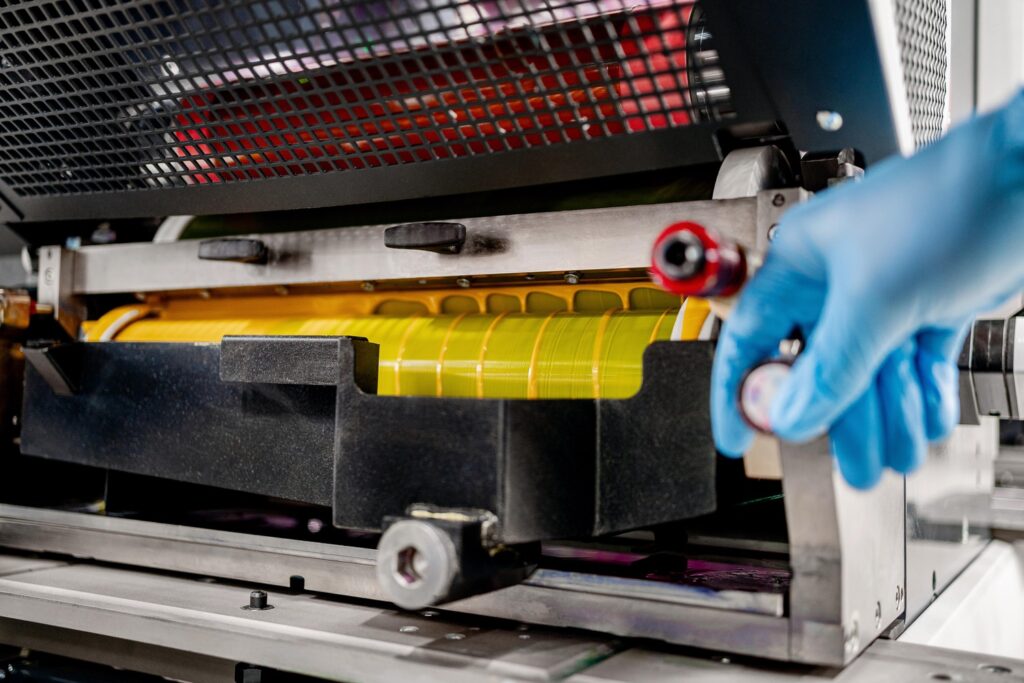

By adding new state-of-the-art, full-scale printing press to the R&D Lab, Masterpress advances the development of new products and facilitates tests of future shrink sleeve, self-adhesive labels and other packaging technologies and materials in simulated production environment.

Masterpress, a leading European provider of printed decorative packaging solutions, announced it expanded the research and development (R&D) lab adjacent to its manufacturing operations in Białystok, Poland. By integrating a bespoke and full-scale printing press dedicated exclusively for R&D purposes, Masterpress is taking a significant step in accelerating innovation within the shrink sleeve and self-adhesive label industry and is well positioned to accelerate the commercialisation of new, sustainable, recyclable products and materials on the market.

“Expanding R&D capabilities is fundamental for us as it fulfils our commitment to continuously enhance our products and services,” said Jeroen de Haan, general manager of Masterpress. “The shrink sleeve and packaging industry evolves, and to progress we must use cutting-edge technologies, test and trial new products, solutions and materials faster and more effectively.”

The new printing press will serve as a versatile tool for research and development across various product groups. Offering flexibility in trying new printing techniques on a scale simulating actual production, without the need to wait for a gap in the regular production schedules, the press allows Masterpress to significantly speed up new product development processes and time-to-market.

“The R&D press enables us to be a much more agile and effective development partner for our customers, quickly turning their creative vision into real product samples. This also improves our collaboration with our suppliers, bringing in the capability to test and trial their new inks or materials before they enter the market,” said Katarzyna Wasilewska, research and development manager at Masterpress.

Masterpress Research and Development Commitment

Masterpress has been consistently investing in its R&D laboratory for over a decade. Along with the new printing press, the research and development laboratory in Białystok is equipped with state-of-the art tools allowing for precise testing of substrate strength, slip and friction as well as simulate resistance of the various products to temperature, solar or shop-floor light.

“By expanding our R&D capabilities we take another step in the long-term growth strategy of Masterpress. We want to drive the market forward with sustainable development and help the label industry to be seen as a positive contributor offering “good-for-recycling” solutions.”

Masterpress’ inventive and “designed-for-recycling” packaging products have been widely recognized by the industry across Europe. The most recent accolade includes the AWA Alexander Watson Associates Sleeve Label Award in the Environmental Winner category for the TINE 300g Dairy Cup Sleeve.

“Expansion of R&D infrastructure for the implementation of product and process innovations.”