The main technical data:

– controlled by a multiprocessor system and driven by servo-motors – Mitsubishi or Siemens

– user-friendly software and a touch screen interface

– internet connectivity for remote diagnostics and troubleshooting

– full control of the line for application and shrinking

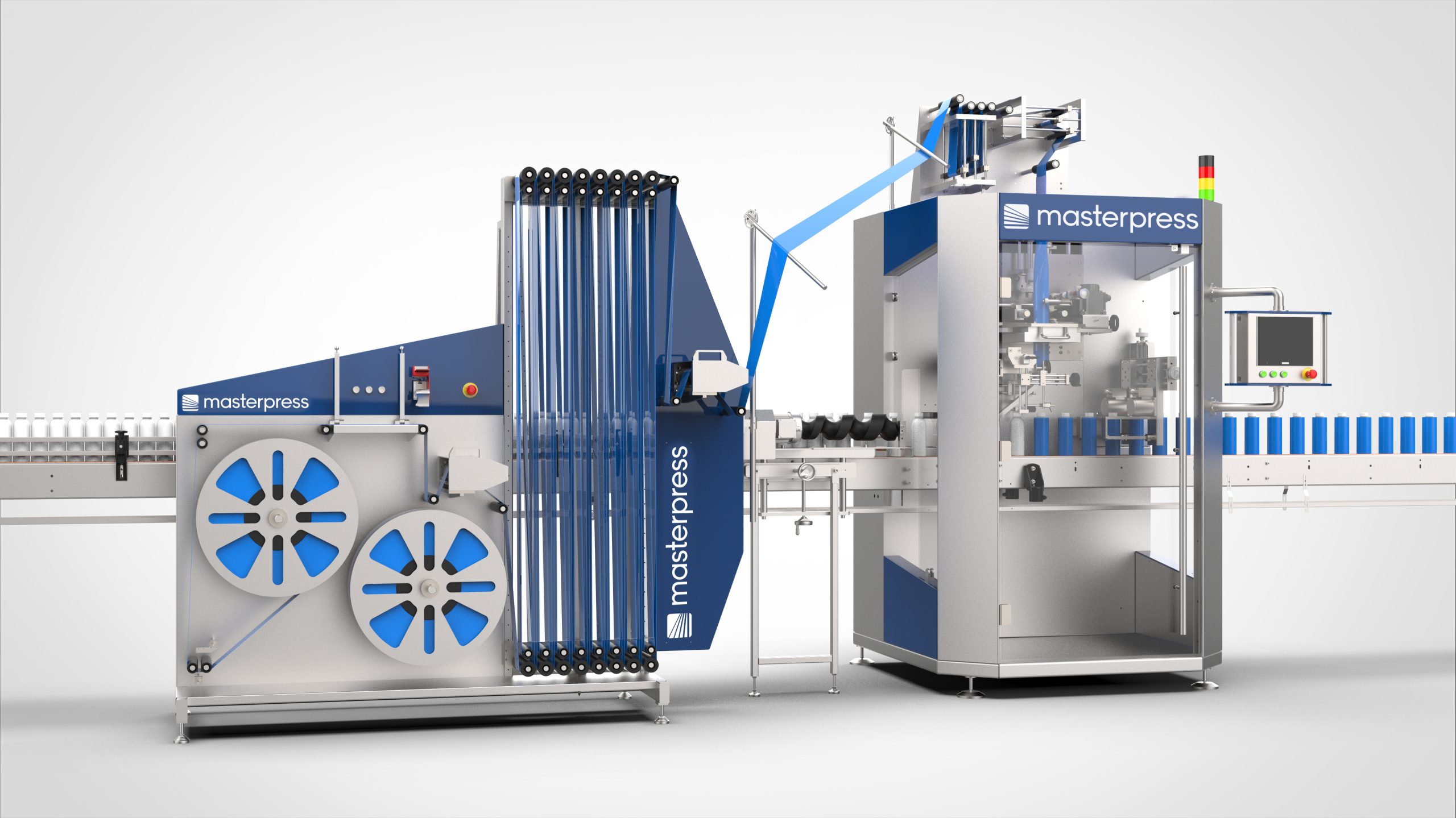

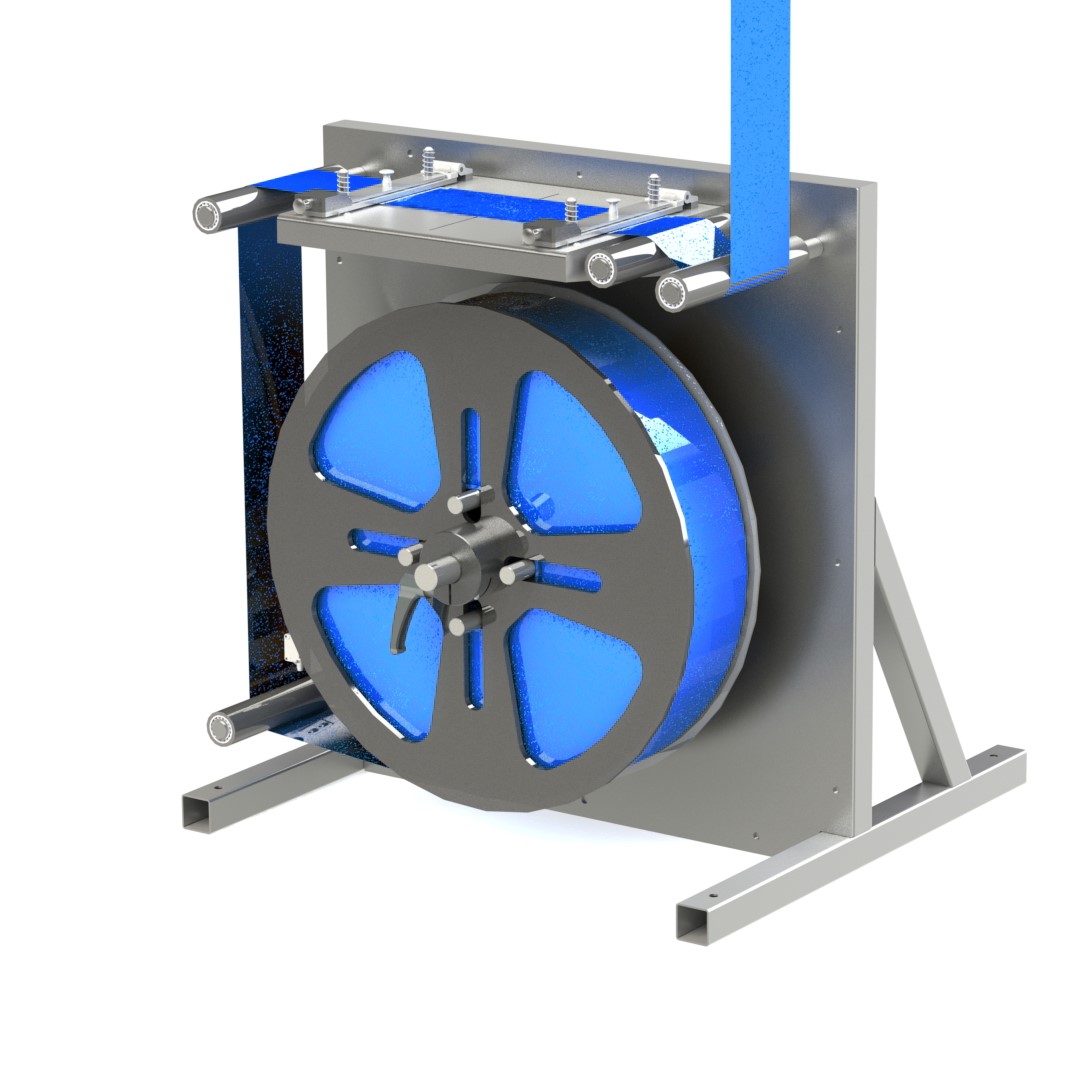

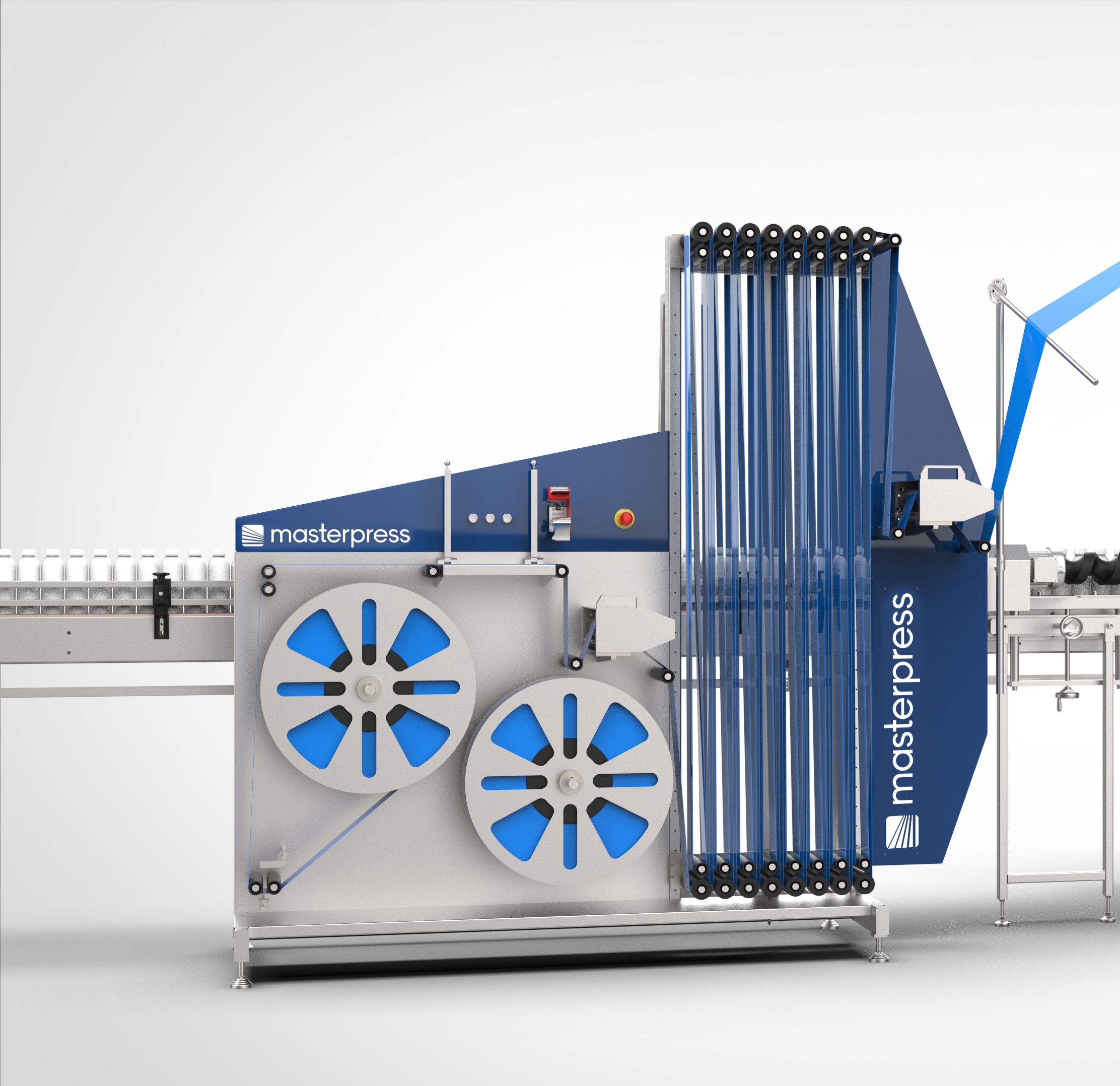

– internal or external unwinder

– operating mode: automatic and manual

– support for label buffer, container buffer and shrink tunel

– quick and easy change of the label form

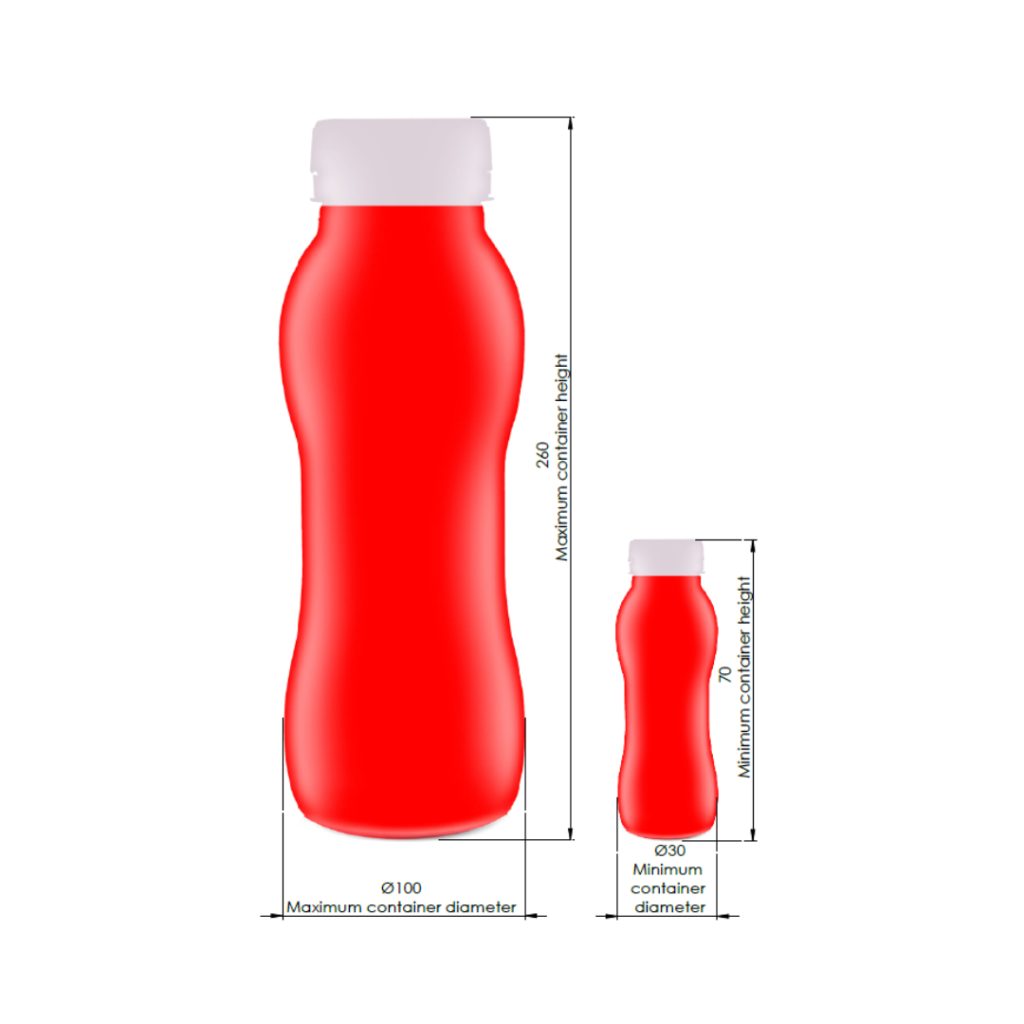

– efficiency: up to 6 000 – 24 000 pcs/h (up to 100 – 400 pcs/min) depending on the type of applicator and dependent on the type of container

– type of material used: rPET, low-density PET, PET, OPS, PVC

– material thickness: 30 μm – 60 μm