Category: Sustainable development

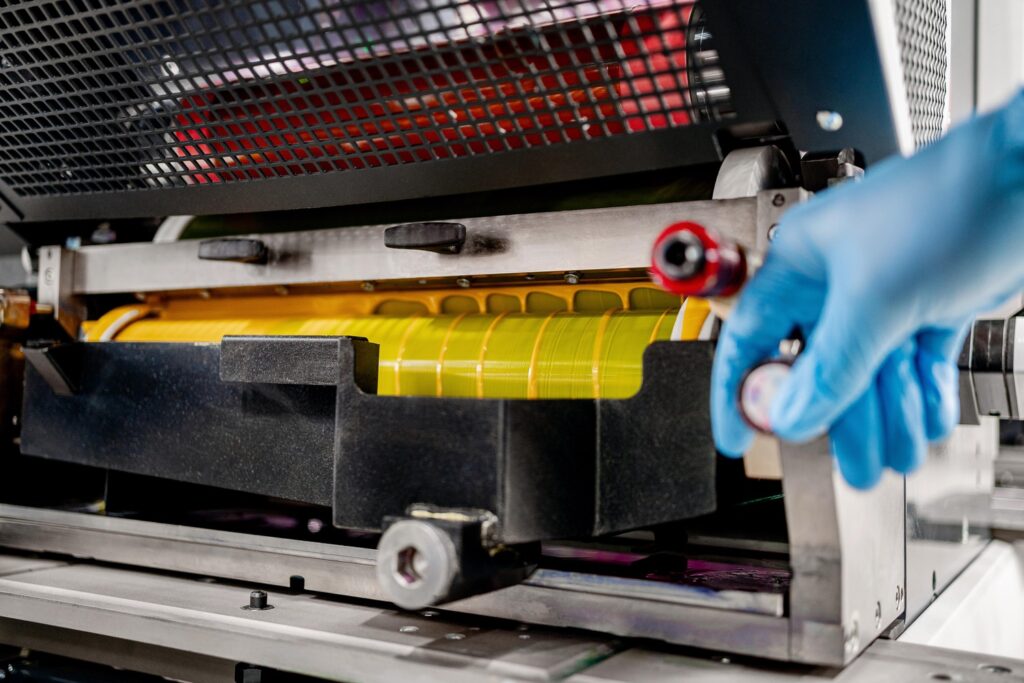

Siegwerk, one of the leading global providers of printing inks and coatings for packaging applications and labels, has announced the launch of its first full UV flexo deinking system for the European market: CIRKIT CLEARPRIME UV E02.

The new primer technology for non-food packaging applications offers a validated solution for safe and economic deinking of UV-printed self-adhesive labels (PSL). As a result, it improves the recyclability of labeled plastic packaging and enables the recovery of high-quality recyclates that are suitable for reuse in non-food packaging applications.

Although UV inks offer some advantageous properties for printing labels, they also pose a challenge for the subsequent recycling. “Depending on the substrate, UV inks are often very difficult to remove and can therefore lead to contaminations of recyclates, which significantly limits their further reuse,” explains Marc Larvor, Head of Technology Narrow EMEA at Siegwerk. “As a result, it is not surprising that UV-printed packaging has so far been considered as problematic in terms of a Circular Economy.” With CIRKIT CLEARPRIME UV E02, Siegwerk now offers a primer solution that specifically addresses this challenge. By enabling easy and safe deinking of UV-printed self-adhesive labels, it eliminates the need for prior label removal if the used plastics are compatible. “Such combined mechanical recycling of labels and plastic packaging can not only help to increase recycling rates, but also to save time and costs,” adds Marc Larvor. “Thereby, our new UV flexo deinking primer actively contributes to realize high-quality recyclates for circular waste streams.”

In a first field test with Masterpress Siegwerk’s new deinking primer has proven its effectiveness in all aspects. Masterpress’ research and development (R&D) experts used uncoated transparent or white pressure sensitive labels (PSL) made of PE85 and applied Siegwerk’s CIRKIT CLEARPRIME UV E02 followed by bleeding resistant UV flexo inks and an UV flexo OPV. First, the primer created a perfect adhesion between substrate and inks and later enabled full ink and varnish removal of the printed polyethylene (PE) film at standard deinking conditions based on the QT 507 washing protocol of the European PET Bottle Platform (EPBP). The primer layer also dissolved residue-free in the hot washing process and thus proved its ability to generate high-quality transparent or white recyclates, while the used non-bleeding ink formulations ensured a clean and reusable washing solution.

In-house laboratory tests at Masterpress and Siegwerk have shown great recyclate results underlining the effectiveness of the new deinking primer. “Consistently investing in its R&D laboratory, Masterpress brings state-of-the-art capabilities to test and trial new inks or materials before they enter the market. We are dedicated to advancing innovation within the shrink sleeve and self-adhesive label industry and are well positioned to help accelerate the commercialization of new, sustainable, recyclable products and materials on the market,” said Katarzyna Wasilewska, research and development manager at Masterpress. “Our tests confirmed an impressive recyclability of the UV-printed PE labels. Compared to other labels with no deinking technology, we could observe that contaminations of plastic recyclates due to discoloration could be massively reduced by using Siegwerk’s UV Deinking Primer.”

Therewith, CIRKIT CLEARPRIME UV E02 makes a significant contribution to improving the quality of recyclates and increasing their reusability. It works perfectly with the company’s established Sicura flexo series such as the non-low migration Sicura Flex 39-8 or the dual-curing series Sicura Flex Dual Cure. In addition, the new primer is compliant with different film materials and allows an inline printing of deinkable materials in a 100% UV-Flexo press setup keeping the complexity for users as low as possible. “With only three minutes, the new UV flexo primer even offers a deinking speed as fast as a water-based deinking primer making it to a great alternative for converters who are using a pure UV flexo press and are not able to process a water-based primer,” adds Katarzyna Wasilewska.

With CIRKIT CLEARPRIME UV E02, Siegwerk has not only added another functional coating solution to its CIRKIT product portfolio for packaging designs in the sense of a Circular Economy, but is also continuing to drive deinking as a new industry standard to further improve the recyclability of plastic packaging. Currently, the company’s portfolio of circular coatings already covers several water-based and solvent-based technologies for different applications, substrates, coating processes and performances: From barrier coatings against liquids, oil and grease, water vapor, oxygen, and UV light through heat seal and protection coatings to delamination and deinking primers.

To learn more about Siegwerk’s coating offering, please visit https://www.siegwerk.com/en/inks-coatings/coatings.html

To meet this challenge requires determination and collaboration along the value chain.

Gabriel Magdaleno, foreign sales director, Masterpress.

——–

According to Eurostat’s 2022 “Packaging Waste Statistics”, in 2021, a staggering 84.3 million tons of waste was generated in the European Union – in other words, an average of 188.7 kg per person and an increase over the previous year of 22.5%. All stakeholders have recognized the urgency of this situation and the corresponding need for an integrated, collaborative approach along all links in the value chain, especially in the context of the EU’s ambitious 2030 goals for packaging and packaging waste. Faced with similar increases in packaging waste for the foreseeable future, the printed decorative packaging industry finds itself in a pivotal role to address this challenge.

Revision of Directive 94/62/EC on Packaging and Packaging Waste (REFIT)

The European Parliament, during its plenary session, endorsed its stance on the proposed regulation and on December 18, 2023, the European Council adopted its position on the proposal. This general approach will set the stage for negotiations between the European Council and Parliament regarding the final form of the Packaging and Packaging Waste legislation. Both institutions must formally approve the final text, assumed to fall within the Belgian Presidency during the first half of 2024. The final text will likely include:

Waste Reduction Targets:

- 5% reduction by 2030

- 10% reduction by 2035

- 15% reduction by 2040

Exemptions for Member States:

- Allowances for exemptions under specific circumstances

- Potential exemptions for organic fruit and vegetables

Collection Targets for Single-Use Plastics:

- EU members to collect 90% of single-use plastic bottles and “metal” beverage containers annually by 2029

Deposit Return Systems:

- Mandatory implementation for the collection of single-use plastic bottles and metal beverage containers

Chemicals in Packaging:

- Measures to address chemicals hindering reuse or recycling

- Commission to collaborate with the European Chemicals Agency, aiming for a report by 2026

Reuse and Refill Targets:

- Varied rules for different product categories

- Exemptions for cardboard

- Excluding wine from the regulations

Industry’s opportunity to lead with innovative technologies that reduce environmental impact

The packaging and printing industry is ready and able to make a significant contribution to reduce the environmental impact of packaging and work with and across industry. By leveraging advanced technologies and strategic approaches, the industry can effectively respond to the growing demands for environmental responsibility and align with the goals of the European Union’s Packaging and Packaging Waste Directive (PPWD).

For example, some of the actions the packaging and printing industry can take to address this challenge:

- The integration of technologies like digital watermarking and switching from UV cured inks to LED inks signifies a leap towards more environmentally responsible practices. Digital watermarking, for instance, streamlines the recycling process by improving the sorting of materials, thereby aligning with the objectives of the EU Directive that emphasizes recycling and waste reduction. The transition to LED inks reflects an industry-wide commitment to more sustainable printing processes by reducing energy consumption, emissions of hazardous materials, waste generation, and air pollution, resonating with the Directive’s push for sustainable practices.

- Material choices in packaging are becoming increasingly crucial. The industry’s exploration of paper versus plastic, and other materials like glass, wood, metal, and bioplastics, is a testament to the search for sustainable and recyclable solutions. This exploration is not just about choosing one material over another; it’s about understanding the lifecycle of each material and how they can complement each other in a circular economy. This approach aligns with the Directive’s focus on reducing waste and enhancing recyclability.

- Consumer engagement through informative and engaging packaging design is another key area. The industry is moving towards designs that not only communicate recycling information clearly but also encourage reuse. This aligns with the aim to involve consumers more actively in waste reduction efforts. The shift in labelling strategies to promote reuse over brand dominance reflects a deeper understanding of the role consumers play in the product lifecycle.

The future of sustainable packaging lies in embracing a diverse range of materials and technologies, each playing a role in reducing environmental impact. As the industry moves forward, it will be essential to balance innovation with practicality, ensuring that new solutions are not only environmentally friendly but also feasible and effective in real-world applications.

Impact of Labels and Films

In the dynamic landscape of the European Fast-Moving Consumer Goods (FMCG) packaging sector, producers are increasingly focused on high-quality labels and innovative printed decorative packaging solutions. These advancements are not just about aesthetics; they encompass designs, colours, and functionality that ensure safety, enhance desirability, and offer robust and unique brand representation.

Labels and films, though smaller in size compared to the overall packaging, play a significant role in the packaging waste stream. They are integral to product branding and information dissemination but pose unique recycling challenges. Labels, for instance, can be made from a variety of materials, including paper, plastic, and foil, often with adhesive backings that contaminate recycling streams. Films, used for wrapping and sealing products, vary widely in material composition, adding another layer of complexity to the recycling process.

As we look towards 2030, it’s imperative to acknowledge the honest role and potential of the labelling, films, and packaging industry in spearheading more environmentally friendly innovations. A key aspect of this evolution involves the reduction of packaging weight (lightweight) and the optimization of packaging for specific products, such as the use of thinner films. Downgauging to thinner materials not only reduces the quantity of material but also minimizes waste. At the same time, we should also look to using a greater proportion of recycled materials, reducing the use of virgin plastic. For example, at Masterpress we are currently running feasibility tests for plastic sleeve labels with 50% recycled content. Additionally, the shift towards recyclable materials has been gaining momentum, with companies exploring new substrates and mono-material packaging solutions that can be easily processed in recycling facilities.

The TINE 300g Dairy Cup Sleeve

Made for Berry Superfos Lidköping and produced by Masterpress, encompasses the company’s commitment to sustainable packaging and reflects “designed-for-recycling” standards set by RecyClass. The packaging introduces a low-density polyolefin shrink sleeve material creating a “mono-material-like” solution that facilitates proper identification and recycling of the cups in the correct polymer stream. Additionally, this sleeve uses thinner, 45µ polyolefin, effectively reducing the amount of material for a lower carbon footprint and more environmentally friendly packaging solutions. The design helps to ensure the cups are correctly recycled, lessening environmental impact and pushing the packaging industry towards more “good-for-recycling” solutions. This design demonstrates how thoughtful material selection and design can result in a fully recyclable product without compromising functionality or aesthetic appeal.

The role of collaboration and the responsibility of all involved parties

However, implementing new technologies alone is not enough to meet the ambitious 2030 goals. Coordination along the value chain is essential for successfully implementing technologies that align with the three Rs (Reduce, Reuse, Recycle) challenge set by the PPWD by 2030. This holistic approach demands an integration of environmental considerations, brand marketing strategies and consumer guidance focused on a more sustainable future. Designing products and packaging that not only appeal to conscientious consumers but also enhance brand value is crucial. Furthermore, these designs must be user-friendly, ensuring ease of use in terms of the three Rs. The ultimate goal is to meet consumer needs by offering products that are not only functional but also environmentally responsible, thereby fulfilling the PPWD’s objectives and contributing to a more sustainable future.

To meet the ambitious goals outlined by the PPWD will therefore require a re-evaluation of the typical “Extended Producer Responsibility” (EPR) doctrine. The EPR has traditionally placed the onus on producers to manage the environmental impacts of their products throughout their life cycle. However, to effectively address the challenges of the three Rs, a more inclusive approach is needed. This calls for the value chain, including regulators and consumers to equally share the responsibility and costs.

Such an approach recognizes that every participant in the product lifecycle – from packaging industries and labelling companies to transportation, retail, consumers, and recycling sectors – plays a vital role in the environmental footprint of products. Each and every link in the value chain should contribute to the solutions and innovations required.

Europe, while leading in regulatory changes like the PPWD, is not alone in this journey. Globally, various regions are implementing similar regulatory changes, emphasizing the importance of sustainable practices across the entire value chain. Europe, with its progressive policies, can set a precedent and lead the world in achieving a more sustainable and environmentally responsible industry standard. By citing global examples and learning from them, Europe can refine its strategies, encouraging a more collaborative and holistic approach to environmental responsibility.

Conclusions

Achieving the ambitious 2030 goals set by the PPWD hinges on the development of flexible solutions that can adapt to diverse regulatory, technological, and cultural needs, both now and in the future. A more nuanced strategy is required, one that considers the unique regulatory landscapes, ongoing technological developments, and cultural practices of different regions.

To successfully navigate these complexities, shared responsibility across the entire value chain is imperative. This means moving beyond the traditional EPR doctrine and fostering collaboration among all stakeholders, including manufacturers, retailers, consumers, and recycling sectors while simultaneously ensuring the engagement of regulators and consumers.

The path to meeting the PPWD’s 2030 objectives is multifaceted, requiring a harmonious blend of shared responsibility, collaborative effort, and relentless innovation. By embracing these principles and understanding that new innovations will continue to advance recycling, it is possible to create a sustainable future that accommodates a variety of needs and paves the way for global environmental stewardship.